DTC Lab and Augsburg University reveal Reciprocal Shell 2023

The Digital Timber Construction Lab (DTC) and Augsburg University of Applied Sciences have recently unveiled a pioneering research demonstrator: a timber grid shell that forgoes the need for steel nodes or special connectors. This innovative structure supports catenary cross-section shells and free-form shapes that were previously unattainable. The project, supported by StadtSparkasse Augsburg, was developed for the Stadtgewaechs summer event at Moritzplatz, Augsburg, promoting sustainability in the city center.

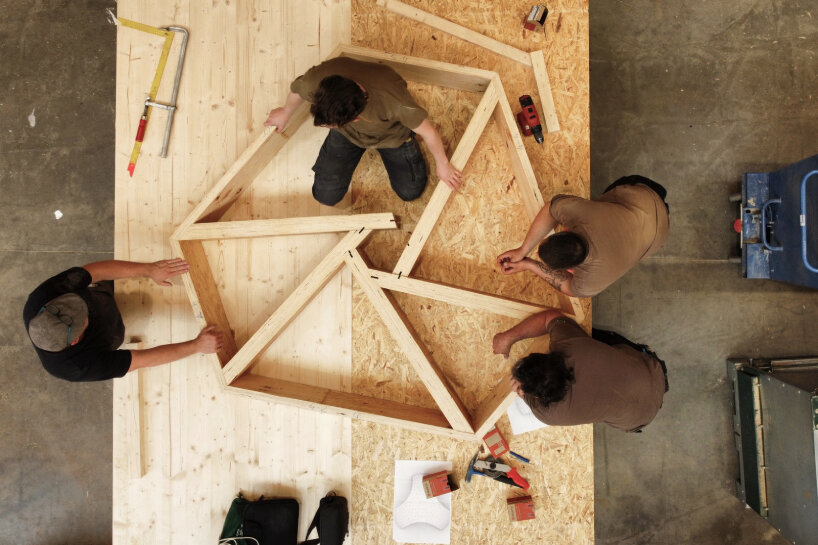

The ReciproFrame Timber Gridshell is an advanced construction system designed for rapid, cost-effective, and material-efficient assembly and disassembly of reusable structures. This hybrid system combines trivalent and reciprocal frame construction methods, leveraging digital technologies to transform short solid timber elements into efficient framed timber systems. These systems facilitate quick assembly and disassembly, enhancing both economic and material efficiency.

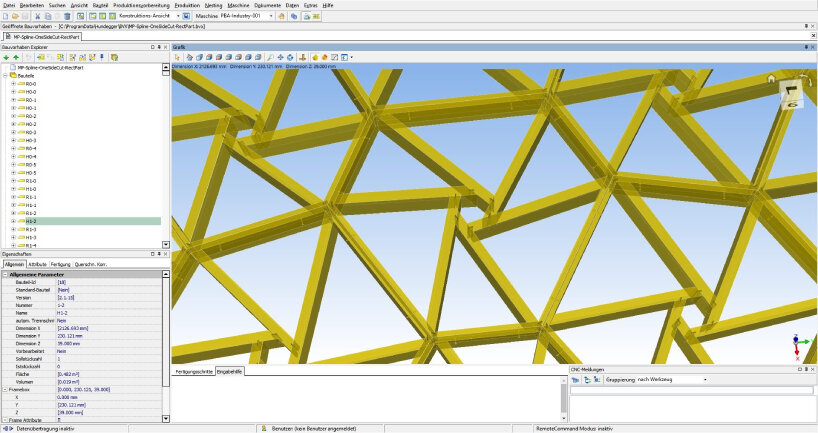

The project builds on previous research (see more here), developing the ‘ReciproFrame’ topology—a reciprocally reinforced trivalent polyhedral frame. Utilizing a CSV file for precise, rapid construction with multi-axis robotic arms, the design resulted in a 7.5-meter small-scale demonstrator. This method achieved structurally efficient catenary cross-sections without steel nodes, a notable improvement over traditional geodesic domes.

Reciprocal Shell 2023 | all images by Amin Adelzadeh, and Hamed Karimian. A

reciproframe Timber shell enables quick, cost-effective assembly

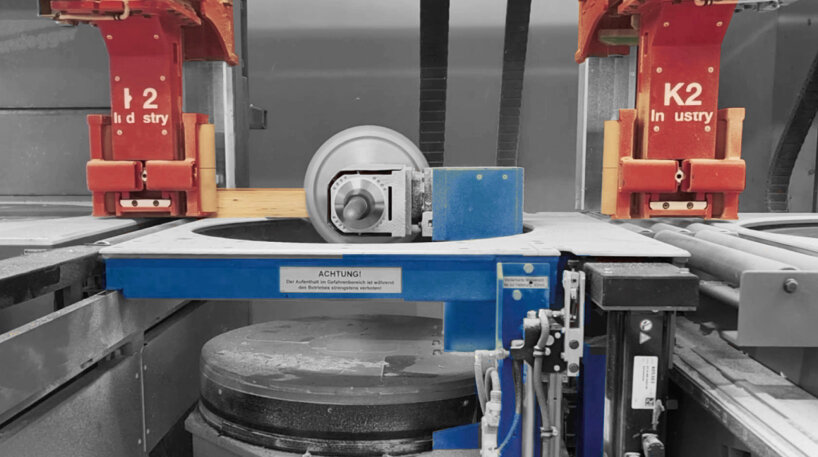

For larger structures, the research introduced a 24-hour industrial fabrication workflow. This process, powered by a custom data interface plugin generating XML-based CAM data, is designed for direct use by Hundegger K2 machines. This addresses interoperability challenges between data programming and industrial joinery operations.

A significant milestone of this project was the construction of a medium-scale demonstrator with a 15-meter span, utilizing 768 Laminated Veneer Lumber (LVL) beams. This system is fully reusable, adhesive-free, lighter, and highly material-efficient compared to cross-laminated timber (CLT) plates, while maintaining similar structural performance. The structure’s span was scaled from 7.5 to 15 meters, and the shell’s area expanded from 20 to 127 square meters, with construction completed in five days.

The XML-based CAM data interface enhances joinery machines’ capabilities, allowing for the processing of larger, denser timber beams, facilitating the construction of larger reusable structures. The project was constructed in the historical core of Augsburg, Germany, serving as a public space for a month before being disassembled, relocated, and stored for future reassembly for permanent use.

Scientific Reference: Adelzadeh. A., Karimian-Aliabadi. H., and Robeller. C., (2024). ReciproFrame Timber Gridshell: From CAM Data Interface Modeling to Operating Industrial Joinery Machine for Scaling up Reusable Timber Structures, In Proceedings of the 29th International Conference of the Association for Computer-Aided Architectural Design Research in Asia (CAADRIA) 2024, Singapore University of Technology and Design (SUTD), Singapore. Volume 3, 329-338.

DTC Lab and Augsburg University reveal a groundbreaking timber grid shell with no steel connectors

this pioneering timber structure supports unique catenary and free-form shapes

the ReciproFrame Timber Gridshell enables quick, cost-effective assembly and disassembly

combining trivalent and reciprocal frame methods for efficient timber construction

digital technologies transform timber into advanced, reusable framed systems

timber grid shell demonstrates a significant advance over traditional geodesic domes

constructed in Augsburg’s historical core, the project served as a public space

the timber structure was disassembled and stored for future reassembly

project info:

name: Reciprocal Shell 2023

design and engineering team: Digital Timber Construction DTC, University of Applied Sciences Augsburg Prof. Dr. Christopher Robeller, Dr. Hamed Karimian A., M.Sc. Amin Adelzadeh

owner: StadtSparkasse Augsburg

production and installation: CLTech GmbH & Co. KG Kaiserslautern

structural approval: IngPunkt Ingenieurgesellschaft für das Bauwesen mbH Dipl.-Ing. Markus Bernhard

foundation – concrete slabs: Lauter Sand Kies Beton GmbH & Co. KG, Bobingen

research funding: Fachagentur Nachwachsende Rohstoffe e.V. (FNR) and Bundesministerium für Ernährung und Landwirtschaft (BMEL). – Timber Structure Interface .TSI, Grant ID 2220HV001X

research partner: Dlubal Software GmbH

scientific development: M.Sc. Amin Adelzadeh, Dr. Hamed Karimian A., Prof. Dr. Christopher Robeller

special thanks to: Agentur Sportbrain, Technisches Hilfswerk THW, Feuerwehr Lechhausen, Ordnungsamt, Bauordnungsamt, and Sozialreferat Augsburg

location: Moritzplatz, Augsburg, Germany

designboom has received this project from our DIY submissions feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: christina vergopoulou | designboom