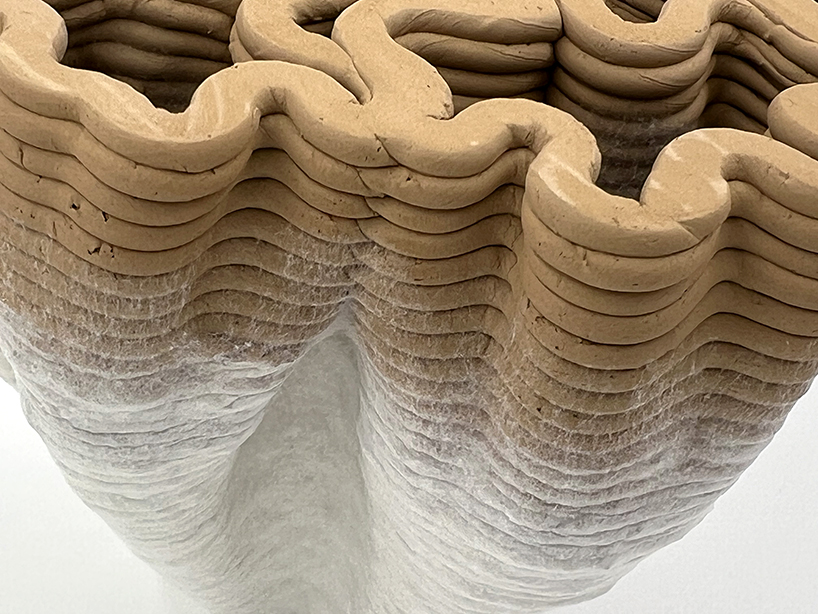

bioMATTERS 3D print vessels and bowls using mycelium, clay and industrial waste materials

KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

happening now! croatian furniture company prostoria stands as an example of a different and more traditional approach based on the evolution from the local factuality of all actors involved in the production process. explore prostoria on designboom!

PRODUCT LIBRARY

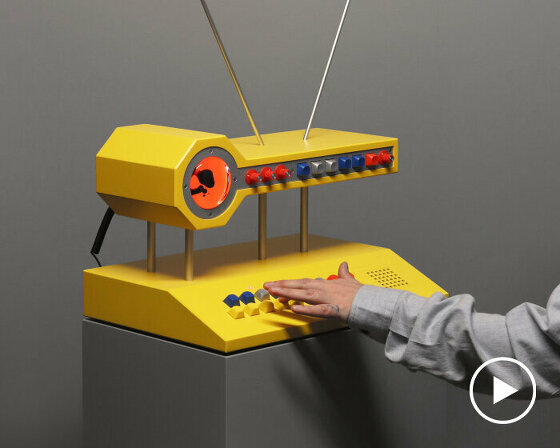

as visitors press the keys, a gooey liquid is brought to life, dancing hypnotically in sync with the chilling tunes.

connections: +240

watch iF Design's panel - power of place - livestreamed and moderated by designboom during NYCxDesign 2024.

connections: 87

designboom speaks to philippe starck about his inspirations, and the priorities of sustainability and peace in today's world.

designboom steps inside the costume institute's latest exhibition, showcasing 250 garments and accessories spanning four centuries, visually united by iconography related to nature.